Potential Applications of 3D Printing Materials

There are many applications of 3D printing. In recent years, 3D printing technologies have made their mark in both commercial and non-commercial domains. Possible applications vary according to printer and material types.

Filaments are used in FDM (Fused Deposition Modelling) printers. These filaments are built from thermoplastics, which are melted to create the desired shapes.

SLA (Stereolithography) and LCD printers use liquid resins. There are various types of resins. Based on the needs of the project, the resin should be carefully selected.

This blog will dive into the potential applications of various 3D printing materials—filament and resins.

PLA

PLA is one of the most widely used FDM printing materials. It is a biodegradable filament that is beginner-friendly, adheres well to the print bed, and produces consistent results.

Home Décor items can be 3D Printed using PLA. Such as spiral vases, kinetic sculptures, plant plots, etc. With such a filament material, it is possible to create versatile designs in multiple colors. GratKit sells a large variety of colors in PLA.

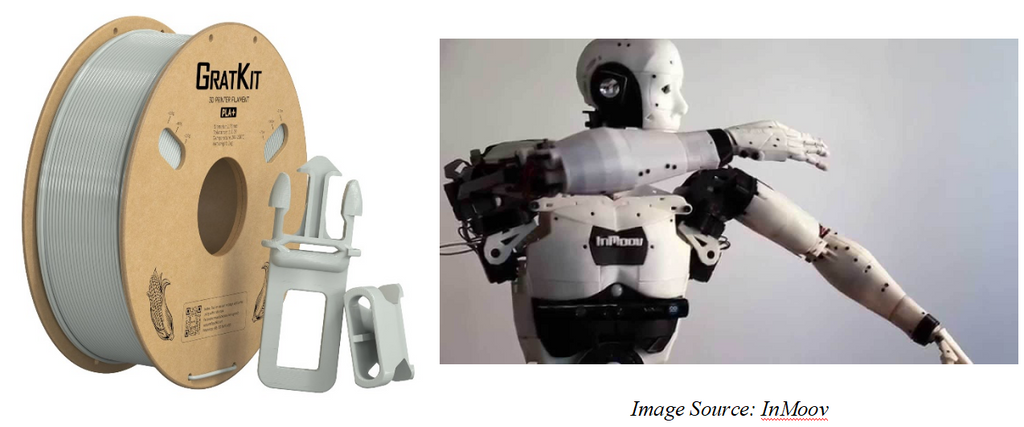

PLA+

PLA+ is also known as PLA plus. It is an enhanced version of PLA, where chemicals have been used to improve its mechanical properties. The PLA+ filament has a larger tensile strength than regular PLA filament.

The enhanced mechanical properties of PLA+ can be used to print robot bodies. Whether it's a hexapod, robotic arm or a quadruped robot, they can all be printed with a durable body.

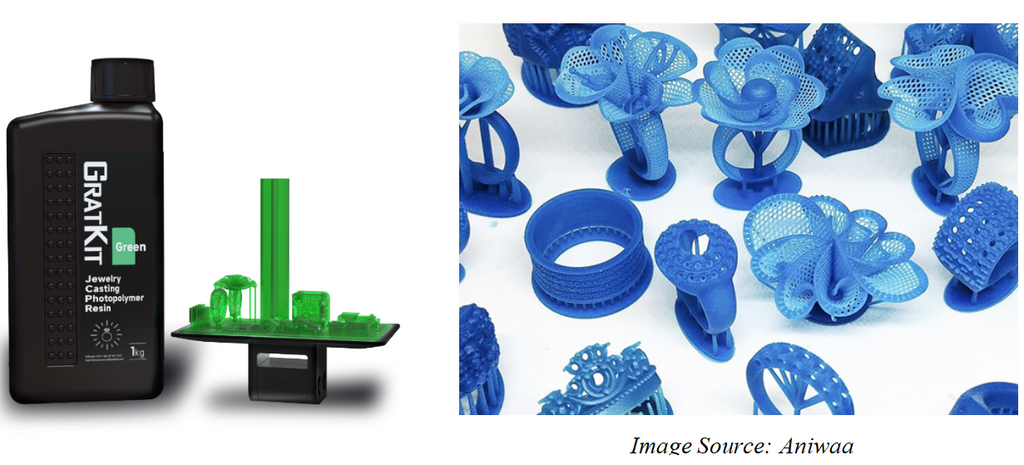

Jewelry Casting Resin

Traditional Jewelry making processes have been disrupted with the advent of SLA, LCD and FDM Printing. 3D Printing with Jewelry Casting Resin allows for intricate, smooth patterns to be printed.

Jewelry casting resin can be used to create masters for moulds. Jewelry makers who run their own business can definitely make use of Jewelry resin and 3D Printers to boost their business.

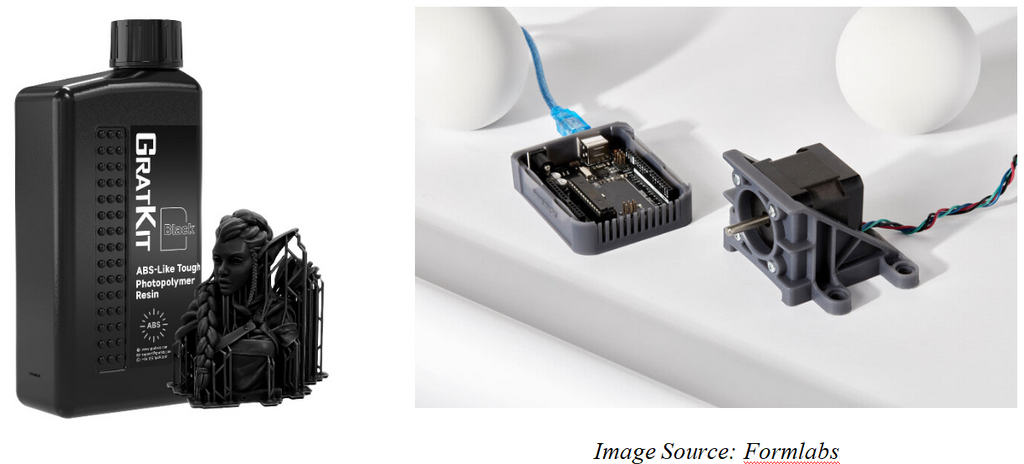

ABS- like Resin:

ABS-like resin, as the name suggests, has similar properties as ABS. Known for its strength, this resin material can be used to print functional parts.

One can create miniatures that are sturdy and resilient. Packaging and casings for electronic components are a common application in 3D printing and electronics communities. Whether it's making snap-fit enclosures for microcontroller boards or motor mounts.

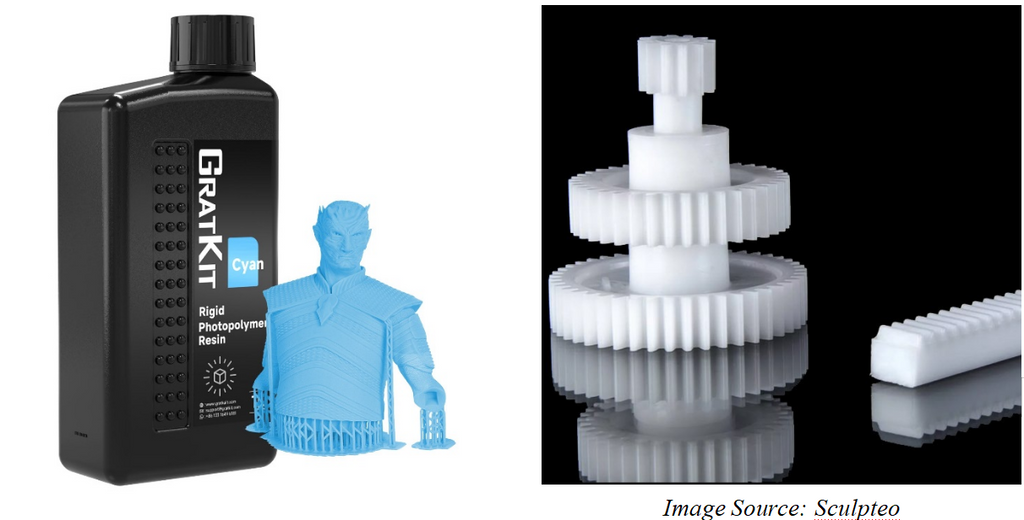

Tough Resin:

Designed to withstand high stress and strain, tough resin has many potential applications. Because of its tensile strength, one can make sturdy, shatter-proof and durable functional parts.

This is a material where one doesn’t have to compromise on the surface finish and mechanical strength.

They are especially suited for the creation of engineering prototypes. Tools, such as wrenches, have been printed previously with tough resin. Tough resin has also been used to print gearboxes. Moving gears are prone to wear damage, so printing with abrasion-resistant material is essential.

The potential ways to use to use filament and resins for different applications are endless. This blog post should have enlightened you on the various possibilities of using resins and filaments. Depending on the mechanical properties of the 3D printing material, one should select the appropriate material to use in their projects.

Leave a comment